The Principle of Fluid Bed Dryer is to operate a fluidal turbulence in a granulated or powdery wet product by means of hot air (or dehumidified air) flowing in an upward direction & to dry the same to the final required degree.

In Fluid Bed Dryer the wet material is transposed to a fluidised state by hot air stream that surrounds the material completely & therefore the heat transfer rate achieved is very high & the temperature distribution throughout the product is uniform. Due to this, drying time is considerably reduced & therefore high production rates are achieved in comparison to other dryers. As the product is in the close contact with hot air at low temperature & also for short duration, the physical & chemical properties of the product are generally not affected & therefore the dryer can effectively be used for the heat sensitive products. Due to movement of product during drying, lump formation, case hardening etc., are minimized. The Fluid Bed Dryers are not suitable for drying of liquids or pasty material.

The Principle of Fluid Bed Granulator is to form desire size of granules by spraying fine mist of binder created by atomized air from spray nozzle located at the top of fluidized powder in product container flowing in a downward direction to agglomerate and then dry to the final required degree. The Fluid Bed Dryer having extra height of retarding chamber with multiport spray nozzle insertion window to accommodate spray gun to be used for spraying of binder downward on the top of suspended particles in fluidized stage.

The Principle of Fluid Bed coater is to coat fluidal fountain shaped turbulence in a pallet or coarse particles by means of fine mist of coating material injected from the bottom of the product container flowing in an upward direction & to dry the same to the final required degree.

The Fluid Bed Dryer having additional extra height of retarding chamber and extra height of conical shaped product container fitted with cylindrical wurster chamber at the center of product container and spray nozzle inserted from the bottom of perforated plate protruded in to the wuster chamber is used to create fountain shaped flow of particles being coated.

Tray Dryer is used for the best drying results in conventional process. It is a double walled cabinet with one or two doors. The gap between two walls is filled with high density fibre glass wool insulation material to avoid heat transfer. Doors are provided with gaskets. Stainless steel trays are placed on the movable trolleys. Dynamically balanced axial flow type blower fans are provided for uniform air circulation in the drying chamber during process. Machine is provided with control panel board with process timer. Digital temperature controller cum indicator etc.

6, 12, 24, 48, 96, 192 trays. Standard & GMP models available with SS 304/SS 316/MS internals & externals. Stainless steel tray in S.S. 304/S.S. 316 quality.

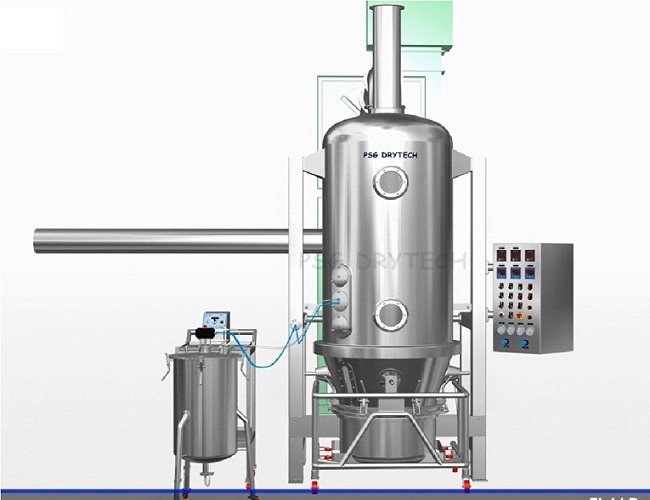

Alliance fluid bed dryers and processor are manufactured in modular construction mainly consisting of main processing (drying) unit and separate inlet air preparation unit and separate exhaust air unit giving flexible and alternative installation option to the customers as per requirement.

Fluid bed processing involves drying, agglomeration, granulation, and coating of particulate materials. It is ideal for a wide range of both heat sensitive and non-heat sensitive products. Uniform processing conditions are achieved by passing hot air through a product layer under controlled velocity conditions to create a fluidized state.

Using intimate air-to-product contact, Drying is carried out by heated air supplied as main the source for drying, as it is effectively introduced by steam heating which gives high rates of heat exchange at high thermal efficiency while preventing overheating of individual particles.

Fluid bed coating of powders, granules, or tablets involves the spraying of a liquid on the fluidized powder under strictly controlled conditions. It is ideal equipment that is in conformity with the requirements of cGMP.

Fluid bed dryer/ Fluid bed processor comes with range of capacities as per our customer’s requirement. Capacity range: - 5 Kg to 500 Kgs